Manufacturing technologies

Advanced technologies for excellent quality standards

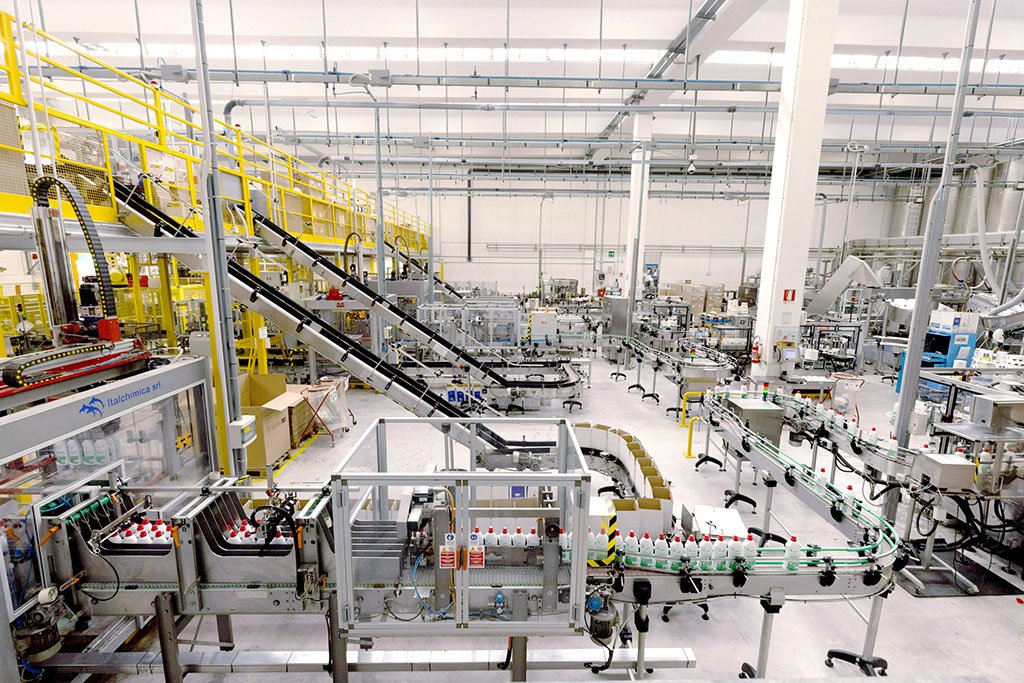

We constantly invest in advanced technologies: these are automation and knowledge-intensive systems with fast innovation cycles. This ensures even product quality standards and safety for operators in manufacturing premises ranging over 25,000 sqm,

guaranteed schedules and volumes, along with optimised logistics covering more than 20,000 sqm. Italchimica innovates to progressively decrease the impact of economic activities, with around 3% of its annual turnover.

25.000

sqm headquarters

100.000

tonne/year manufacturing capacity

10

packaging production lines

13

in-house bottle manufacturing plants

20.000

sqm logistics hub

92.000

pallets/year

Product creation chain

1. Information Technology

All company departments are coordinated through the ERP SAP HANA management system, thus optimising production and operations management in all facilities.

2. Research, development and regulatory affairs

In the R&D department, a team of Quality, Formulation, Regulatory Affairs and Sustainability experts designs the most advanced formulas.

3. Marketing & Sales

The Marketing Department and the Sales Department manage the needs and wishes of customers, working out the best innovative solutions to meet their needs and ensure that products have everything they need to be successful.

4. Graphics and Communication

The Communication department is in charge for creating creative visual concepts, developing graphic layouts and product content intended to be communicated externally.

5. Purchase and management of raw materials

Once approved by the R&D department and bought by the Purchasing department, the raw materials arrive at the warehouse. Here, they are properly stored and sent for processing and mixing to produce the formulas.

6. Production planning and development

The Production department plans, monitors and coordinates production activities with a view to optimising the resources (from a human, economic and technological point of view) involved.

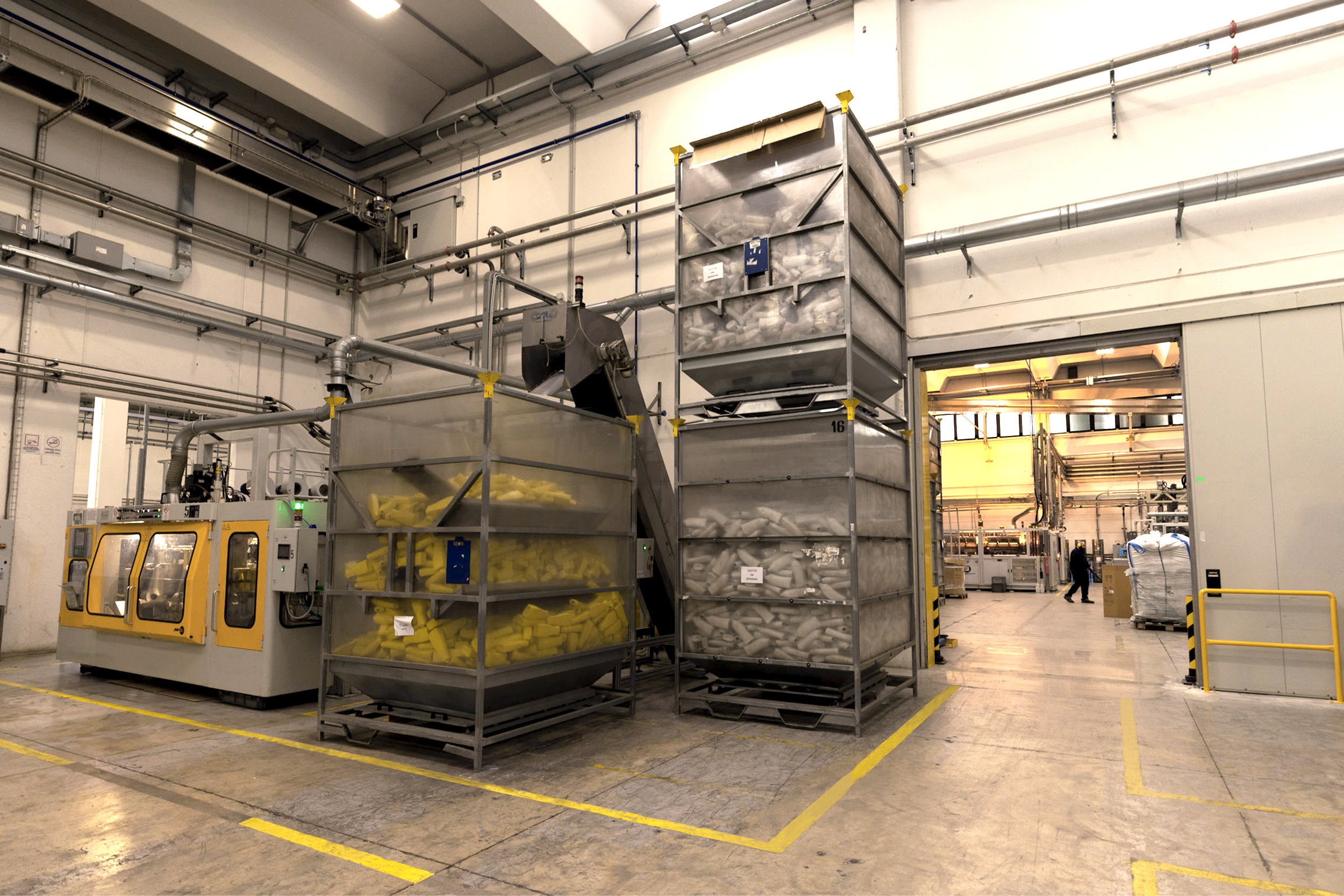

7. Blow moulding

The Blow Moulding department is in charge of the production of the various bottle formats. Different extrusion and stretching process techniques allow for the moulding of recycled HDPE and PET plastic containers.

8. Mixing

The Mixing Department handles the input from planning by preparing the mixtures/formulas and managing process documentation.

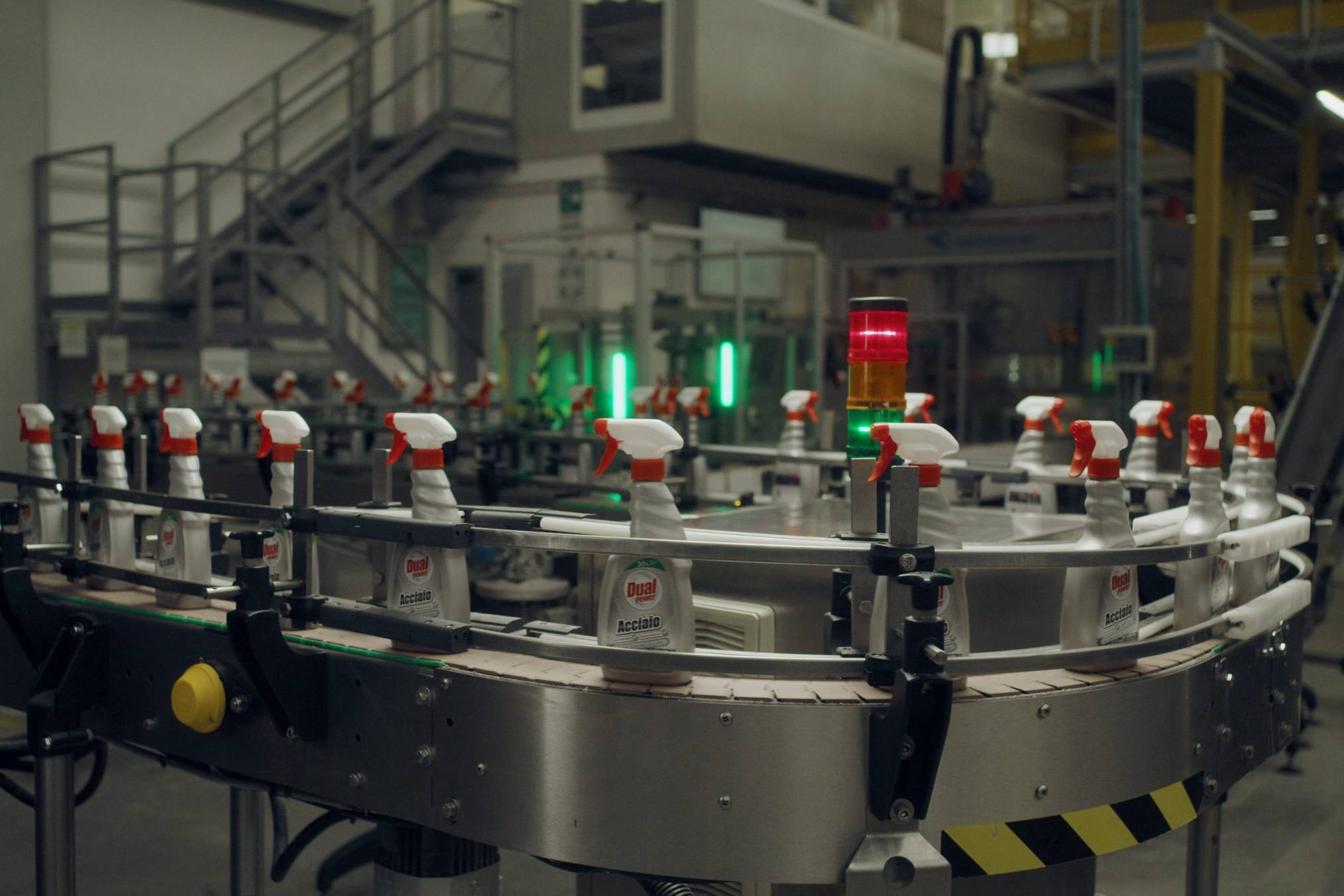

9. Filling and Packaging

The resulting formulas are sent to the Filling and Packaging Department, where they are transferred into different packaging formats according to their type.

10. Quality Control

Quality Control over the entire process identifies and monitors the quality standards of the products made.

11. Finished product management and Logistics

Finished and packaged products are sent to the warehouse pending collection by customers. The Logistics department is responsible for the storage of goods and their proper transport through the distribution network.